CNC Services and Laser Engraving: Unveiling the Precision and Versatility of Modern Laser Engraving Machines

Introduction to Laser Engraving Technology

Laser engraving technology has revolutionized the way we personalize and customize a wide range of materials. This advanced manufacturing process employs high-energy laser beams to create intricate designs, logos, text, and patterns on various surfaces with unparalleled precision and detail. From artistic creations to industrial applications, laser engraving machines offer versatility and reliability that traditional methods cannot match.

Laser Engraving Technology and Applications

The core of laser engraving technology lies in its ability to deliver focused laser beams onto a surface, causing localized material removal through vaporization, melting, or chemical changes. This non-contact process eliminates the need for mechanical tooling, allowing for greater flexibility in design and rapid prototyping. Here are some key applications:

- Personalization: Engraving names, dates, and messages on jewelry, awards, and keepsakes.

- Industrial Marking: Applying serial numbers, barcodes, and logos on electronic components, tools, and machinery.

- Artistic Creations: Producing intricate designs and patterns on wood, glass, leather, and acrylic.

- Prototyping: Creating detailed models and mockups for product design and development.

- Branding: Enhancing brand recognition through customized packaging, signage, and promotional items.

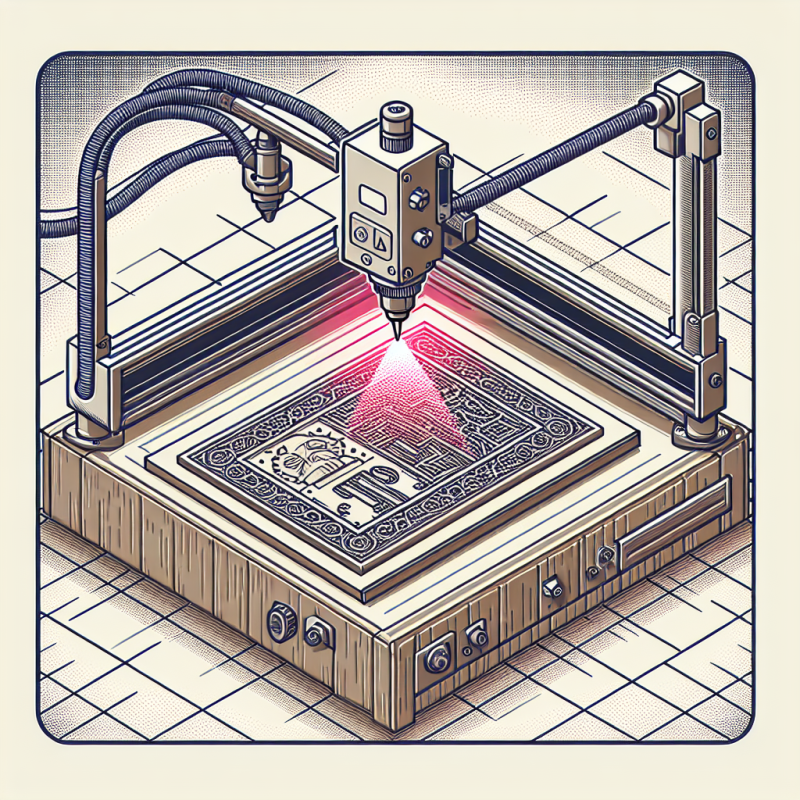

Machine Specifications and Features

Modern laser engraving machines come in various sizes, power ratings, and configurations to cater to diverse needs. Key specifications and features to consider include:

- Laser Power: Measured in watts, higher power levels enable faster engraving speeds and deeper cuts.

- Work Area: Determines the maximum size of the material that can be engraved.

- Beam Quality: Affects the precision and detail of the engraving. Machines with a higher beam quality can produce finer details.

- Software Compatibility: Ensures seamless integration with design software for easy job setup and management.

- Automation: Features like automatic focus adjustment, material handling systems, and multi-axis capabilities enhance productivity.

Our flagship model, the Hawk P2S P2, offers a robust combination of these features, making it ideal for both small-scale customization and high-volume production. Visit cnc services and laser engraving for more details.

Material Compatibility

Laser engraving machines are compatible with a vast array of materials, each requiring specific settings to achieve optimal results. Here are some commonly engraved materials:

- Wood: Popular for its natural beauty and ability to accept a wide range of finishes.

- Metal: Including stainless steel, aluminum, and brass, often used for industrial marking and branding.

- Plastics: Such as acrylics and polycarbonates, ideal for signage and prototypes.

- Glass: Suitable for decorative engravings and awards.

- Leather: Frequently used for personalized items like wallets and belts.

Safety Considerations

Operating a laser engraving machine involves several safety considerations to protect both operators and equipment. Here are some best practices:

- Personal Protective Equipment (PPE): Always wear laser safety goggles, gloves, and appropriate clothing to shield from laser radiation and flying debris.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of harmful fumes and particulates.

- Fire Precautions: Have fire extinguishers and smoke detectors readily available, and regularly clean the machine to prevent dust buildup.

- Training: Provide comprehensive training to operators on machine operation, safety protocols, and emergency procedures.

- Machine Enclosures: Use enclosed work areas to contain laser beams and minimize exposure.

Industry Best Practices

To maximize the efficiency and longevity of your laser engraving machine, adhere to these industry best practices:

- Regular Maintenance: Perform routine checks and maintenance tasks, such as cleaning lenses, lubricating moving parts, and inspecting cables.

- Software Updates: Keep your machine’s control software up-to-date to benefit from new features and bug fixes.

- Material Testing: Conduct tests on new materials to determine the optimal settings for engraving.

- Job Optimization: Use nesting software to maximize material utilization and reduce waste.

- Quality Control: Implement quality control measures to ensure consistency in output.

Cost-Benefit Analysis

Investing in a laser engraving machine can offer significant long-term benefits, despite the initial cost. Here’s a cost-benefit analysis to consider:

- Customization Capabilities: Laser engraving enables highly personalized products, increasing customer satisfaction and fostering brand loyalty.

- Production Efficiency: Automated processes and rapid setup times reduce labor costs and improve throughput.

- Material Versatility: The ability to engrave a wide range of materials expands product offerings and market reach.

- Scalability: Machines can be scaled to meet growing demand, minimizing the need for additional equipment.

- Return on Investment (ROI): With increased sales and operational efficiencies, the ROI period for a laser engraving machine can be relatively short.

Maintenance Tips

Maintaining your laser engraving machine is crucial for optimal performance and longevity. Here are some practical tips:

- Daily Inspections: Check for any signs of wear, debris buildup, or unusual noises.

- Lens Cleaning: Regularly clean lenses with appropriate solutions to ensure clear beam transmission.

- Alignment Checks: Verify the alignment of the laser beam and optics to maintain precision.

- Filter Replacements: Replace air filters as needed to maintain clean air circulation within the machine.

- Software Backup: Regularly back up your control software and design files to prevent data loss.

Project Ideas and Tutorials

To get started with your laser engraving machine, here are some inspiring project ideas and tutorials:

- Customized Jewelry: Engrave names, dates, and quotes on pendants, bracelets, and rings.

- Personalized Home Decor: Create engraved signs, picture frames, and coasters with meaningful messages.

- Engraved Gifts: Personalize gifts like cutting boards, mugs, and keychains for special occasions.

- Industrial Marking: Apply barcodes, serial numbers, and logos on tools, equipment, and parts.

- Artistic Creations: Experiment with intricate designs and patterns on wood, acrylic, and leather.

For detailed tutorials and project inspiration, visit our online resource center or join our community forums to connect with fellow laser engraving enthusiasts.

Questions About Laser Engraving Machines

Here are some frequently asked questions to help you better understand laser engraving machines:

- What materials can be engraved with a laser machine? A wide range of materials, including wood, metal, plastics, glass, and leather, can be engraved with varying degrees of success depending on the machine’s specifications and settings.

- How precise are laser engraving machines? Modern laser engraving machines offer high precision, capable of producing intricate details and fine