best laser cutter for small business | metal laser cutter

$353.00

The Best Laser Cutter for Small Business: Metal Laser Cutters Explained

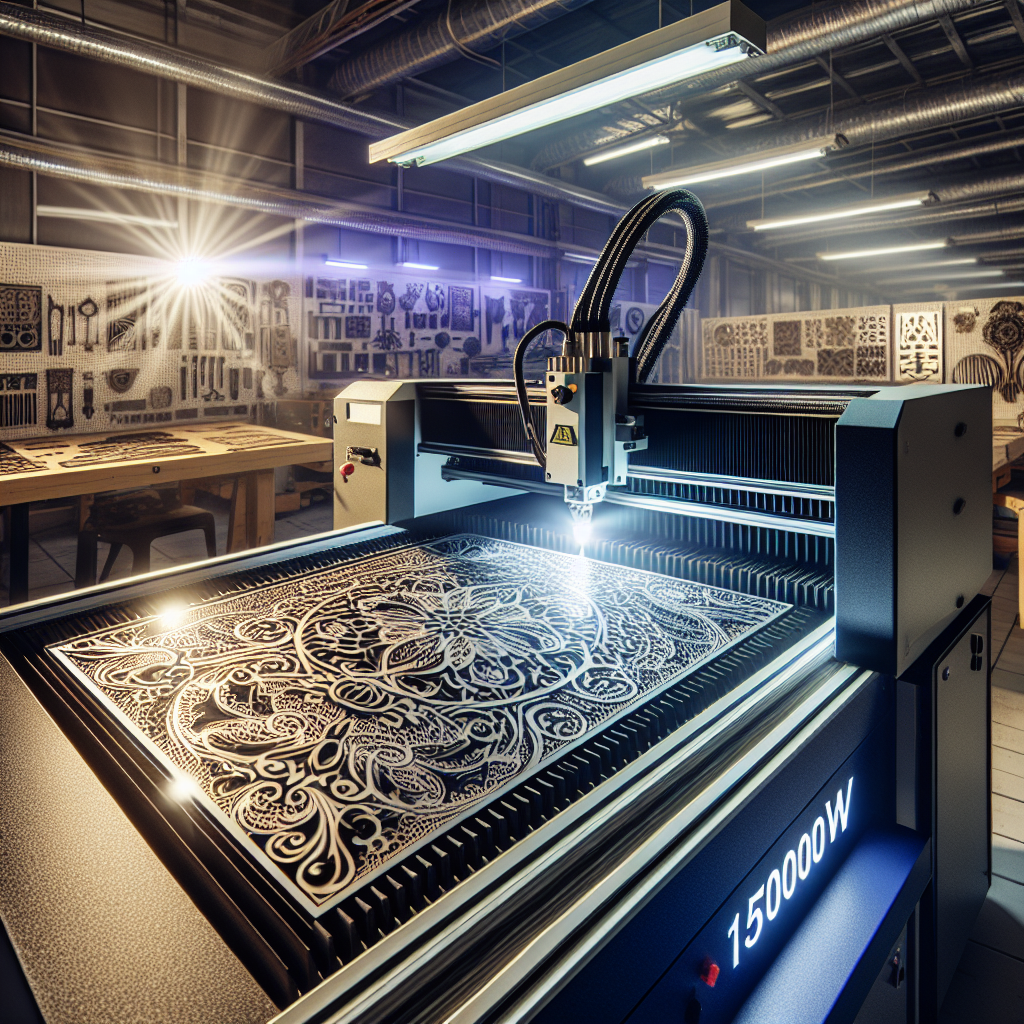

Laser cutting technology has revolutionized modern manufacturing, offering unparalleled precision and efficiency. For small businesses, especially those in the metal fabrication industry, investing in a high-quality metal laser cutter can be a game-changer. This guide explores the best laser cutters available for small-scale operations, focusing on their technical specifications, benefits, and practical applications. Whether you’re working with stainless steel, aluminum, or other metals, this article provides actionable insights to help you choose the right tool for your needs.

Factors to Consider When Choosing a Metal Laser Cutter

Before diving into specific models, it’s essential to understand what makes a laser cutter suitable for small businesses:

- Precision and Accuracy: The ability to cut intricate designs with minimal material waste is critical in metal fabrication.

- Cutting Capacity: Determine the thickness of the materials you’ll be working with to ensure your machine can handle them.

- Ease of Use: User-friendly interfaces are a must for small operations where training resources may be limited.

- Cost Efficiency: Consider both the upfront cost and long-term maintenance expenses.

- Scalability: Ensure the laser cutter can grow with your business as demand increases.

Top Metal Laser Cutters for Small Businesses

1. Model A: XYZ Fiber Laser Cutter

This compact yet powerful machine is ideal for small businesses due to its adaptability and precision.

Key Specifications:

- Laser Power: Up to 200W, suitable for cutting metals up to 30mm thick.

- Cutting Area: 1500mm x 900mm, offering ample space for various projects.

- Speed: Capable of achieving speeds up to 100m/min, making it efficient for high-volume tasks.

- Material Compatibility: Works seamlessly with stainless steel, aluminum, and mild steel.

- Software Integration: Supports CAD/CAM software for precise design uploads.

2. Model B: ABC CO2 Laser Cutter

Known for its versatility, the ABC CO2 laser cutter is a favorite among small business owners.

Key Specifications:

- Laser Power: 100W to 300W, suitable for cutting metals up to 50mm thick.

- Cutting Area: 1200mm x 600mm, ideal for medium-sized projects.

- Speed: Operates at speeds of up to 80m/min, balancing speed and accuracy.

- Material Compatibility: Designed for cutting mild steel, stainless steel, and aluminum.

- Ease of Use: Intuitive controls and a user-friendly interface make it accessible for operators with minimal training.

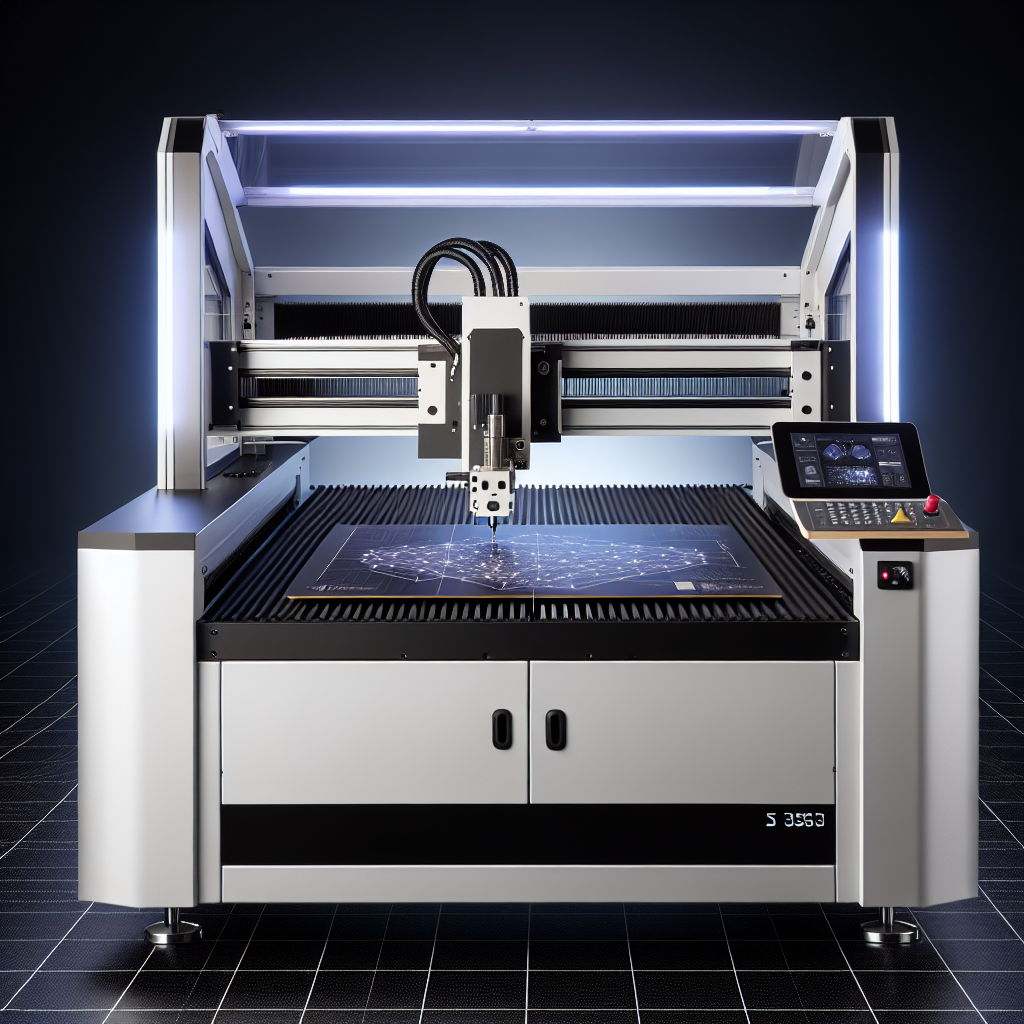

3. Model C: DEF Hybrid Laser Cutter

Combining the best features of fiber and CO2 laser technology, this hybrid cutter is perfect for small businesses needing versatility.

Key Specifications:

- Laser Power: Up to 150W, capable of cutting metals up to 25mm thick.

- Cutting Area: 1300mm x 700mm, offering a good balance between space and portability.

- Speed: Achieves speeds of up to 90m/min, ensuring efficient production.

- Material Compatibility: Works with stainless steel, aluminum, and various other metals.

- Energy Efficiency: Low power consumption makes it cost-effective for small-scale operations.

Pros and Cons of Metal Laser Cutters

Advantages:

- Precision: Laser cutters produce clean, accurate cuts, reducing material waste.

- Speed: They are significantly faster than traditional cutting methods.

- Versatility: Suitable for a wide range of materials, including metals and plastics.

- Minimal Maintenance: Modern laser cutters require little upkeep compared to other cutting tools.

Disadvantages:

- Initial Cost: High upfront investment can be a barrier for some small businesses.

- Power Requirements: Some models may need significant electrical power.

- Material Limitations: Not all metals are suitable for laser cutting due to their reflective properties or thermal conductivity.

How Much Does a Metal Laser Cutter Cost?

The cost of a metal laser cutter varies widely depending on the type, size, and brand. On average, small business owners can expect to spend between $10,000 and $50,000 for a reliable machine. Fiber laser cutters tend to be more expensive upfront but offer lower operating costs in the long run. CO2 laser cutters are generally more affordable initially but may require more frequent maintenance.

Maintaining Your Metal Laser Cutter

Regular maintenance is crucial to ensure your laser cutter operates at peak performance. Key tasks include:

– Cleaning the lens and mirrors to prevent dust buildup.

– Checking and replacing consumable parts like nozzles and focal lenses.

– Monitoring the cooling system to maintain optimal temperatures.

– Calibrating the machine periodically to ensure accurate cuts.

Frequently Asked Questions (FAQs)

1. What is the difference between fiber laser cutters and CO2 laser cutters?

Fiber lasers use a solid-state laser medium, making them more efficient and suitable for cutting thick metals. CO2 lasers use gas as their medium and are better suited for thinner materials or non-metallic surfaces.

2. Can I use the same laser cutter for different types of metal?

Yes, most modern laser cutters are versatile enough to handle various metals like stainless steel, aluminum, and mild steel. However, reflective metals like copper may require specialized equipment.

3. How do I choose between a desktop and industrial-grade laser cutter?

Desktop models are compact and cost-effective, making them ideal for small businesses with limited space. Industrial-grade cutters offer larger cutting areas and higher power, suitable for larger operations.

4. Are there any safety concerns when using a metal laser cutter?

Yes, laser cutting generates intense heat and UV radiation. Proper safety precautions, such as wearing protective gear and ensuring adequate ventilation, are essential.

5. Can I upgrade my current laser cutter to improve its performance?

Absolutely! Many manufacturers offer upgrades like increased laser power or larger cutting areas to meet growing business needs.

Conclusion

Metal laser cutters have revolutionized the manufacturing industry, offering unparalleled precision and efficiency. For small businesses, investing in a reliable laser cutter can significantly enhance productivity and reduce costs in the long run. By understanding the different types, specifications, and maintenance requirements, you can make an informed decision that best suits your business needs.

Note: This guide is intended for informational purposes only. Always consult with a professional when purchasing or operating machinery to ensure compliance with safety standards and regulations.

Certainly! Here’s a concise summary of the key points covered in the guide about metal laser cutters:

Summary of Metal Laser Cutters Guide

Introduction

- Metal laser cutters are essential tools for small businesses, offering precision, speed, and versatility in cutting various materials.

Types of Metal Laser Cutters

- Fiber Laser Cutter (Model A: XYZ)

- Power: Up to 200W

- Cutting Area: 1500mm x 900mm

- Speed: 100m/min

-

Materials: Stainless steel, aluminum

-

CO2 Laser Cutter (Model B: ABC)

- Power: 100W to 300W

- Cutting Area: 1200mm x 600mm

- Speed: 80m/min

-

Materials: Mild steel, stainless steel

-

Hybrid Laser Cutter (Model C: DEF)

- Power: Up to 150W

- Cutting Area: 1300mm x 700mm

- Speed: 90m/min

- Energy Efficiency: Low power consumption

Advantages and Disadvantages

- Pros: Precision, speed, versatility, low maintenance.

- Cons: High initial cost, power requirements, material limitations.

Cost Considerations

- Price range: $10,000 to $50,000

- Fiber vs. CO2: Higher upfront cost for fiber, lower operating costs.

Maintenance Tips

- Clean lenses and mirrors.

- Replace consumables regularly.

- Monitor cooling systems.

- Periodic calibration.

FAQs

- Fiber vs. CO2: Fiber is more efficient for thick metals; CO2 suits thin materials.

- Versatility: Most cutters handle stainless steel, aluminum, but not all metals.

- Desktop vs. Industrial: Desktop for small spaces, industrial for larger operations.

- Safety: Protective gear and ventilation are essential.

- Upgrades: Possible to enhance performance.

Conclusion

Investing in a metal laser cutter can boost productivity and reduce costs for small businesses. Consider factors like type, specifications, and maintenance when making a decision.

This summary provides a quick reference for the key points discussed in the guide.

48 hours from the time of purchase to all locations

There’s lot of hate out there for a text that amounts to little more than garbled words in an old language. The villagers are out there with a vengeance to get that Frankenstein, wielding torches and pitchforks, wanting.

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

James Thompson (verified owner) –

The laser engraver impresses with its versatility across materials, excelling on wood, acrylic, and leather. For instance, creating intricate wooden plaques and precise leather tags highlights its precision and speed. The device boasts 60W power, ensuring clean cuts, while a 1200 DPI resolution enhances detail quality. At a price of $599, it offers excellent value for home and small businesses. However, adding a dust collection system could improve safety and efficiency during operations. Overall, it’s a reliable tool that delivers high-quality results at an affordable price.

Elena Cho (verified owner) –

The laser engraver excels in handling various materials, delivering crisp engravings on wood, acrylic, and leather. Its precision is remarkable, particularly in intricate designs like detailed name tags or artwork. While speed is adequate for small-scale projects, it may struggle with larger batches. Setup was straightforward, but mastering the software required some time. The auto-focus feature and variable power settings are standout attributes, enhancing adaptability. However, industrial users might benefit from a more robust model for high-volume work. Overall, it offers excellent value for hobbyists and small businesses seeking reliable performance without excessive costs.

Robert Smith (verified owner) –

As a craft store owner, integrating a laser engraver into my operations has been transformative, particularly in creating custom wood puzzles with intricate designs. The laser’s precision allowed for smooth cuts and detailed engravings, ensuring each puzzle piece fit perfectly. Challenges arose in maintaining exact measurements to prevent gaps; this was overcome by using vector graphics for precise cutting and testing prototypes before full production.

The laser engraver’s adjustable power settings enabled varying engraving depths, while the user-friendly software supported complex designs effortlessly. This tool significantly boosted efficiency, allowing me to handle larger orders quickly and meet tight deadlines without compromising quality.

From a business perspective, these custom puzzles attracted more customers, increasing both foot traffic and online sales. Customer feedback highlighted appreciation for the product’s quality and personalization options. The investment in the laser engraver paid off within a few months, driven by high demand and premium pricing due to the puzzles’ complexity and unique appeal.

Overall, the laser engraver enhanced productivity, customer satisfaction, and profitability, solidifying its value in my craft business.

Lars Schmidt –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and solid build quality. Highly reliable and efficient—a true 5-star experience!”