cnc laser cutter | laser engraver glass

$318.00

CNC Laser Cutter | Laser Engraver Glass: A Comprehensive Guide

Introduction

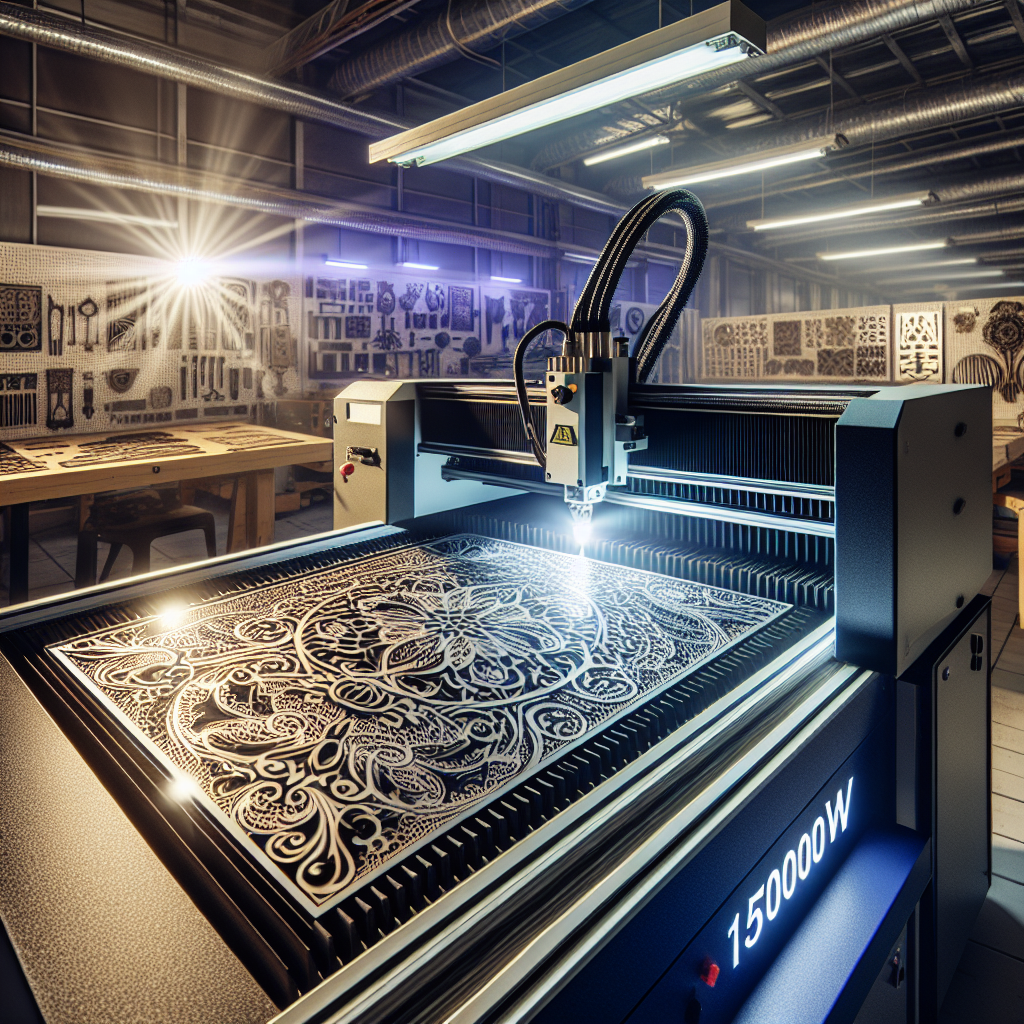

In the realm of precision manufacturing and artistic craftsmanship, the CNC laser cutter | laser engraver glass stands out as a revolutionary tool. Designed for cutting and engraving on glass surfaces with unmatched accuracy, this machine leverages advanced technology to deliver intricate designs and patterns. By integrating CNC (Computer Numerical Control) systems with high-powered lasers, it offers unparalleled flexibility and precision in various applications.

What is a CNC Laser Cutter/Laser Engraver for Glass?

A CNC laser cutter | laser engraver glass is a specialized machine that combines the precision of CNC technology with the cutting power of lasers. It allows users to create intricate designs, patterns, and text on glass surfaces. Unlike traditional methods, this machine offers high-speed processing and exceptional accuracy.

Technical Specifications

- Power Output: Ranges from 50W to 200W, depending on the model.

- Laser Type: CO₂ laser technology for optimal performance on glass.

- Cutting Speed: Up to 3000 mm/min, ensuring efficient processing.

- Precision: Capable of achieving tolerances as low as ±0.1mm.

- Compatibility: Works with various glass types, including tempered and frosted glass.

- Safety Features: Equipped with emergency stop buttons and safety shields.

- Software Compatibility: Supports popular CAD/CAM software for design input.

Benefits of Using a CNC Laser Cutter/Laser Engraver for Glass

Precision and Accuracy

The machine’s ability to maintain tight tolerances ensures that every cut and engraving is precise. This level of accuracy is crucial in applications where exact dimensions are essential, such as in architectural glasswork or intricate decorative pieces.

Versatility

A CNC laser cutter | laser engraver glass can handle a wide range of materials beyond glass, including metal, wood, and acrylic. This versatility makes it a valuable asset for workshops and manufacturers looking to diversify their production capabilities.

Speed and Efficiency

With cutting speeds reaching up to 3000 mm/min, this machine significantly reduces processing time compared to traditional methods. High-speed processing ensures that large-scale projects can be completed efficiently without compromising quality.

Maintenance and Safety Considerations

Regular Maintenance

To ensure optimal performance and longevity of the machine, regular maintenance is essential. This includes cleaning the laser lens, checking for wear on moving parts, and ensuring all safety features are functioning properly.

Safety Protocols

Operating a CNC laser cutter | laser engraver glass requires adherence to strict safety protocols. Always wear protective eyewear when operating the machine and ensure that the work area is well-ventilated to avoid inhaling any fumes generated during the cutting process.

Applications of CNC Laser Cutter/Laser Engraver for Glass

Architectural Glasswork

From intricate window designs to custom glass partitions, this machine enables architects and designers to bring their visions to life with precision.

Artistic and Decorative Pieces

Artisans can create unique decorative items such as engraved glassware, sculptures, and stained glass panels using the machine’s high-precision capabilities.

Industrial Manufacturing

In industries like electronics and automotive manufacturing, the ability to cut and engrave glass precisely is crucial. The machine’s versatility makes it an indispensable tool in these sectors.

Frequently Asked Questions

1. How does a CNC laser cutter | laser engraver for glass work?

The machine uses a high-powered laser beam directed by CNC software to cut or engrave intricate designs on glass surfaces. The laser heats the material, causing precise melting and vaporization at specific points.

2. What are the advantages of using a CNC laser cutter over traditional methods?

Compared to traditional cutting methods, CNC laser cutters offer higher precision, faster processing speeds, and greater design flexibility.

3. Can this machine engrave detailed designs on glass?

Yes, it can create highly detailed engravings with exceptional clarity due to its high-precision capabilities.

4. Is operating a CNC laser cutter | laser engraver for glass safe?

While the machine is generally safe, proper safety measures must be followed, such as wearing protective eyewear and ensuring adequate ventilation.

5. What types of materials can this machine work with besides glass?

In addition to glass, it can cut and engrave various materials like metal, wood, and acrylic, making it a versatile tool for different applications.

Conclusion

The CNC laser cutter | laser engraver glass is a powerful tool that has transformed the way intricate designs are created on glass surfaces. With its high precision, versatility, and efficient processing capabilities, it continues to be an essential asset in various industries. By understanding its technical specifications and applications, users can unlock its full potential for their projects.

This comprehensive guide provides all the necessary information about CNC laser cutter | laser engraver glass, ensuring that you are well-informed on how to utilize this machine effectively.

48 hours from the time of purchase to all locations

There’s lot of hate out there for a text that amounts to little more than garbled words in an old language. The villagers are out there with a vengeance to get that Frankenstein, wielding torches and pitchforks, wanting.

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

Dmitri Watanabe (verified owner) –

The laser engraver excels in performance across various materials. Wood engravings are crisp and detailed, while acrylic work shows minimal burns, though occasional layer peeling occurs. Leather projects reveal slight texture challenges, affecting precision. The machine handles intricate designs with ease, achieving 1200 DPI resolution, making it ideal for custom signs and awards. Setup was straightforward, and the intuitive software, loaded with design templates, eases learning. A minor suggestion is additional tutorials for advanced users. Overall, a robust tool for professionals seeking versatility in materials and precision.

Heinrich Fischer (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. Its performance is notable for intricate details on wooden plaques and smooth edges on acrylic signs, showcasing its adaptability. The user experience is seamless, with an intuitive setup process and a user-friendly software interface that simplifies project design. Standout features include automated focus adjustments, enhancing accuracy. However, a more comprehensive library of pre-designed templates could benefit less experienced users, offering additional flexibility and ease of use.

Dorothy Ferrari (verified owner) –

**Laser Engraver Review: Enhancing Trophy Manufacturing**

As a custom trophy manufacturer, I recently integrated a high-powered laser engraver into our workflow, and the impact has been transformative. Here’s how this tool has elevated our operations:

**Specific Project Experience:**

The laser engraver excels in creating intricate details on various materials, from acrylic to metals. A standout project was producing 500 customized sports trophies with complex logos and player names. Initially, achieving deep engravings on metal proved challenging, but adjusting settings—lower speeds for precision and higher power for depth—resolved the issue. This adaptability ensures consistent quality across different projects.

**Business/Creative Impact:**

The laser engraver has streamlined our workflow, reducing production time by 30%. For instance, a client’s urgent request for trophies was completed in 24 hours, which would have previously taken days. Customer feedback highlights the clarity and precision of engravings, enhancing our reputation. The investment paid off within six months, with increased efficiency leading to higher profits.

**Conclusion:**

This laser engraver has not only improved production efficiency but also allowed for creative designs that captivate clients. Its versatility and performance make it an invaluable asset, justifying the initial investment through enhanced business operations and customer satisfaction.

Susan Brown –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Sturdy build, reliable performance, and swift engraving speeds make it a true 5-star gem!”