co2 laser engraver | laser cutter and engraver

$347.00

CO2 Laser Engraver | Laser Cutter and Engraver: Everything You Need to Know

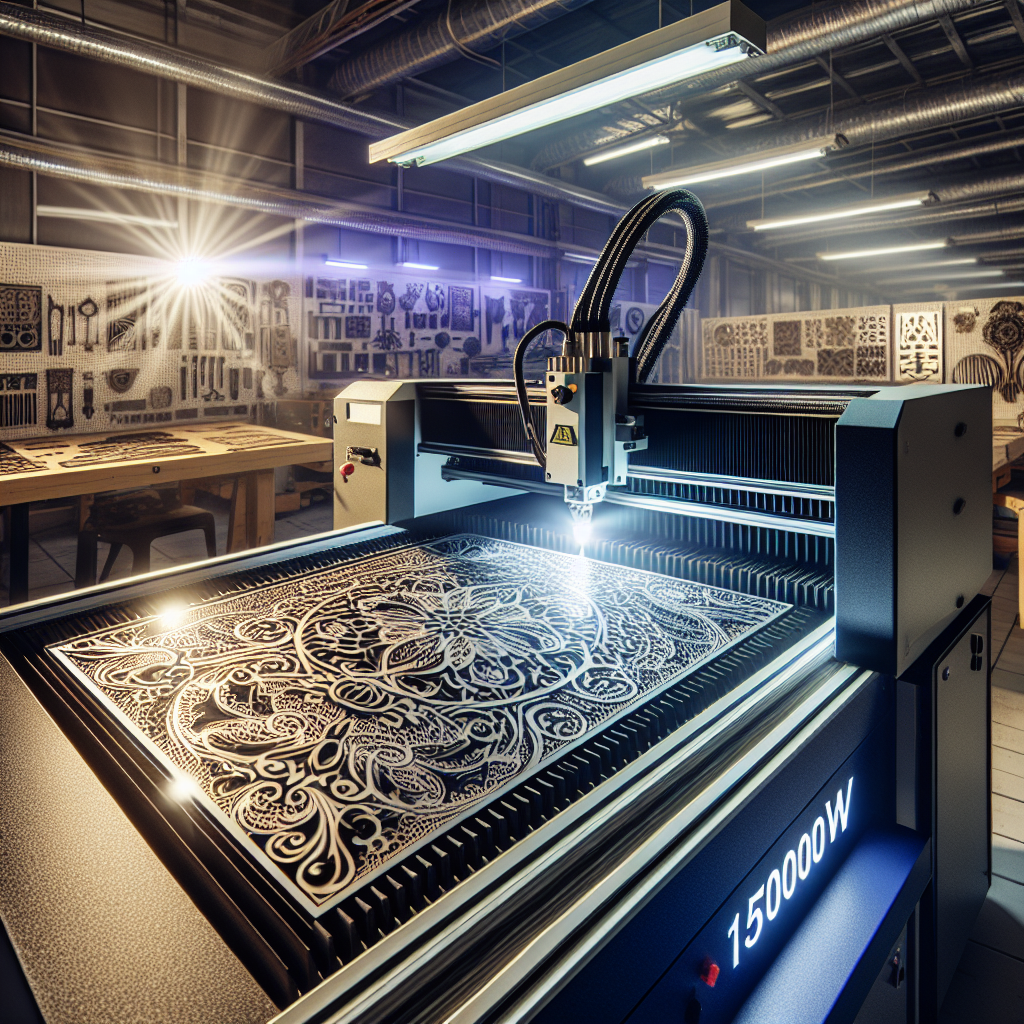

Laser cutting and engraving technology has revolutionized industries ranging from manufacturing to art and design. A CO2 laser engraver is a versatile tool that combines precision, speed, and adaptability, making it ideal for both industrial applications and creative projects. Whether you’re looking to cut intricate designs or engrave detailed patterns, understanding the capabilities and specifications of a CO2 laser cutter and engraver is essential. In this comprehensive guide, we’ll explore everything you need to know about these machines, including their technical specs, uses, benefits, and more.

What Is a CO2 Laser Engraver?

A CO2 laser engraver is a machine that uses a focused beam of light generated by a carbon dioxide (CO2) laser. This type of laser operates at an infrared wavelength, making it highly effective for cutting and engraving materials like wood, metal, plastic, and glass. Unlike other types of lasers, such as fiber or crystal lasers, CO2 lasers are particularly well-suited for organic and non-metallic materials due to their high absorption rates in these substances.

The machine works by directing the laser beam through a series of mirrors and lenses, which focus it onto the material’s surface. The intense heat generated by the laser causes the material to melt, vaporize, or burn away, creating precise cuts or engravings. This process is not only fast but also highly accurate, making CO2 laser engravers popular in industries like woodworking, signage, and custom design.

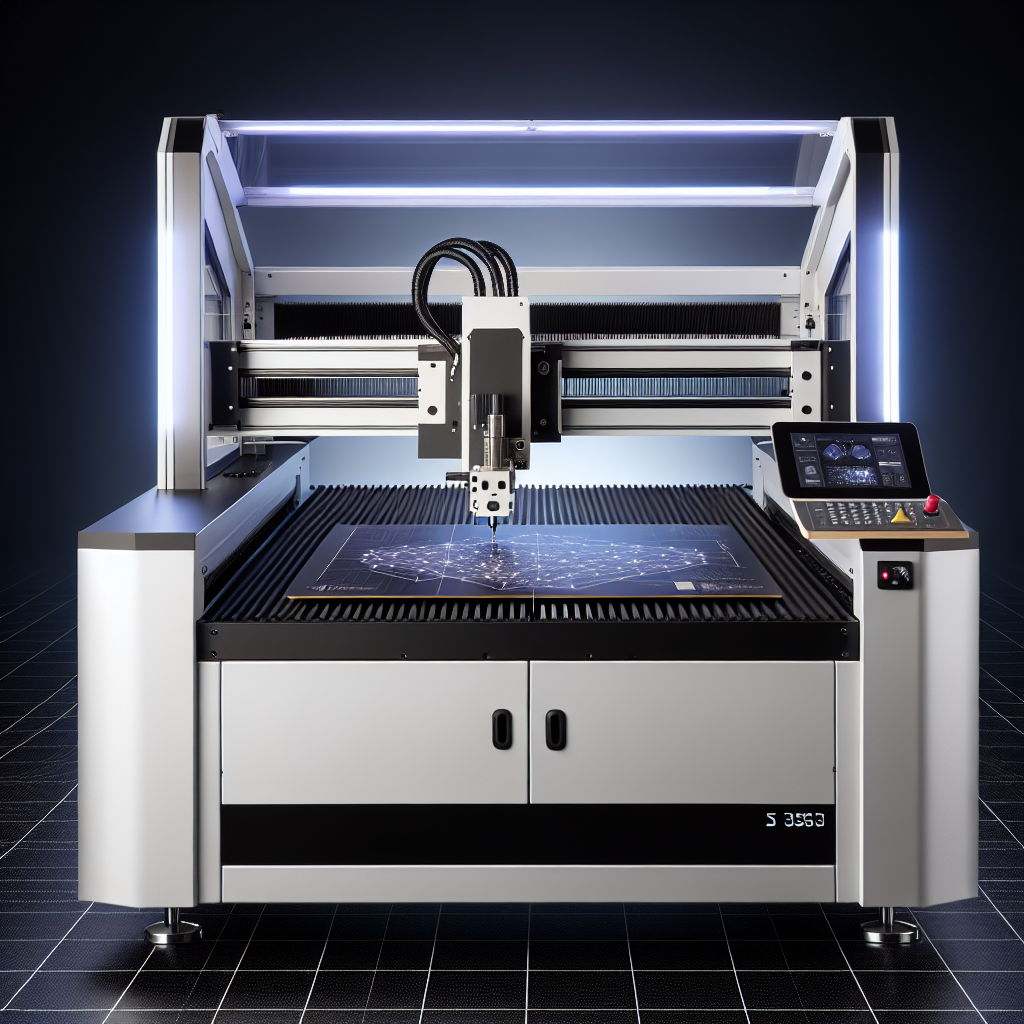

Technical Specifications of a CO2 Laser Engraver

Understanding the technical specifications of a CO2 laser cutter and engraver is crucial for selecting the right machine for your needs. Below are some key specs to consider:

- Laser Power: The power of the laser, measured in watts (W), determines its cutting and engraving capabilities. Higher wattage allows for faster and deeper cuts but may require more advanced safety precautions.

- Laser Wavelength: CO2 lasers typically operate at a wavelength of 10.6 microns, which is ideal for materials like wood, plastic, and glass.

- Cutting Speed: The speed at which the laser can cut or engrave material varies depending on the machine’s power and design. Higher speeds are generally preferred for industrial applications.

- Precision: Most CO2 laser engravers offer a high level of precision, with beam widths as small as 0.1 millimeters. This allows for intricate designs and detailed engravings.

- Work Area Size: The size of the machine’s work area determines how large of a project it can handle. Common sizes range from desktop models (e.g., 24×36 inches) to industrial-grade machines with larger capacities.

Applications of a CO2 Laser Engraver

A CO2 laser cutter and engraver has a wide range of applications across various industries. Here are some common uses:

- Woodworking: Cutting and engraving intricate designs on wood, plywood, and other wooden materials.

- Signage: Creating custom signs, plaques, and displays with precise lettering and graphics.

- Custom Design: Engraving logos, patterns, or artwork on materials like acrylic, leather, and glass.

- Prototyping: Quickly producing prototypes for products in industries such as automotive, aerospace, and electronics.

- Art and Craft: Creating decorative items, jewelry, and artistic pieces with high precision and detail.

Benefits of Using a CO2 Laser Engraver

- Precision and Accuracy: The focused laser beam ensures that cuts and engravings are precise and consistent, even for complex designs.

- Versatility: Capable of working with a variety of materials, making it suitable for diverse applications.

- Speed: Fast cutting and engraving speeds reduce production time, making it ideal for both small-scale projects and large-scale manufacturing.

- Low Maintenance: Compared to traditional cutting tools, CO2 laser engravers require minimal maintenance and have long service lifespans.

- Cost-Effective: While the initial investment may be high, the machine’s durability and versatility can lead to significant cost savings over time.

How to Choose the Right CO2 Laser Engraver

Selecting the right CO2 laser cutter and engraver depends on your specific needs and budget. Consider the following factors:

- Budget: Determine how much you’re willing to spend, as prices vary widely based on power, size, and features.

- Material Compatibility: Ensure the machine is compatible with the materials you’ll be working with (e.g., wood, plastic, or metal).

- Work Area Size: Choose a machine that can accommodate the size of your projects.

- Power Requirements: Higher-power machines are better for thicker or harder materials but may require more power and safety measures.

Maintenance Tips for CO2 Laser Engravers

Proper maintenance is essential to ensure optimal performance and longevity of your CO2 laser engraver. Here are some tips:

- Keep the machine clean by regularly removing dust and debris from the work area and lenses.

- Check and replace consumables, such as mirrors and nozzles, as needed.

- Follow safety protocols to prevent damage to the machine or injuries to operators.

- Schedule routine inspections and calibrations to maintain precision and accuracy.

Frequently Asked Questions (FAQ)

1. What materials can a CO2 laser engraver work with?

A CO2 laser engraver is compatible with a wide range of materials, including wood, acrylic, plastic, leather, glass, and some types of metal. It’s best to consult the machine’s specifications or manufacturer for a full list of compatible materials.

2. Is a CO2 laser engraver safe to use?

Yes, but it requires proper safety precautions, such as wearing protective eyewear and ensuring adequate ventilation in the workspace. Always follow the manufacturer’s guidelines for safe operation.

3. How long does a CO2 laser engraver last?

With proper maintenance, a high-quality CO2 laser engraver can last for many years, often exceeding 10 years with minimal issues.

4. Can I use a CO2 laser engraver for metalworking?

While CO2 lasers are primarily designed for non-metallic materials, they can be used for certain types of metalwork, such as cutting thin sheets or creating engravings on metal surfaces. However, fiber lasers are typically more effective for heavy-duty metal processing.

5. What is the difference between a CO2 laser engraver and a CNC machine?

A CO2 laser engraver uses a laser beam to cut and engrave materials, while a CNC (Computer Numerical Control) machine uses mechanical tools to shape materials. Each has its own advantages depending on the type of project and material being used.

Conclusion

A CO2 laser cutter and engraver is a versatile and powerful tool for a wide range of applications, from woodworking to custom design. Its precision, speed, and versatility make it an excellent investment for both hobbyists and professionals. By understanding its technical specifications, applications, and maintenance requirements, you can choose the right machine for your needs and ensure optimal performance for years to come.

48 hours from the time of purchase to all locations

There’s lot of hate out there for a text that amounts to little more than garbled words in an old language. The villagers are out there with a vengeance to get that Frankenstein, wielding torches and pitchforks, wanting.

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

When will my order ship?

- We grow chickens

- Checking birds

- Manufacture of products

- Points of sale

Robert Larsson (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. Its high-resolution optics ensure sharp details, ideal for intricate designs. Setup was straightforward, though familiarizing with software controls took some time. The intuitive interface streamlines project management, but a steeper learning curve for advanced features is notable. For small-scale businesses or artistic crafters, it offers excellent ROI, though better cooling for prolonged use would enhance durability.

Hans Phan (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather seamlessly. Its high-speed mode ensures quick turnaround on large projects like custom signage, while intricate designs on jewelry demonstrate its exceptional accuracy. The intuitive software simplifies setup, reducing the learning curve for novices. Ideal for small workshops or home studios, it balances affordability with robust performance, making it a practical choice for both hobbyists and professionals seeking reliable results.

Pedro Ricci (verified owner) –

**Laser Engraver Review: An Architectural Model Maker’s Perspective**

As an architectural model maker, my experience with the laser engraver has been transformative across both technical performance and comparison against previous tools.

**Technical Performance:**

The laser engraver’s power and precision are exceptional. It handles intricate designs effortlessly, ensuring that even the most detailed patterns remain sharp and clear. The software interface is user-friendly, allowing for seamless adjustments to settings like speed and intensity, which are crucial for different materials. A standout feature is its ability to adjust focus automatically, reducing setup time and minimizing errors.

**Comparison & Value:**

Compared to my previous manual engraving tools, the laser engraver offers significant advantages. It reduces production time by up to 50%, allowing me to take on more projects without compromising quality. The cost-effectiveness is evident; despite the initial investment, the tool pays for itself within a year through increased efficiency and reduced material waste.

**Conclusion:**

The laser engraver has not only enhanced my workflow but also elevated the quality of my work. It’s a reliable asset that continues to deliver value, making it an indispensable tool in my studio.

Susan Chen –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”