The Ultimate Guide to Laser Cutter Acrylic: Precision, Versatility, and Creativity in Your Hands

If you’re looking for a versatile tool that combines precision with creativity, a machine might be the perfect addition to your workshop or creative space. These machines are designed for high-quality cutting and engraving on various materials, including wood, plastic, leather, and of course, acrylic. Whether you’re a hobbyist, a small business owner, or a professional artist, this guide will help you understand the benefits, applications, and considerations when using a laser cutter acrylic machine.

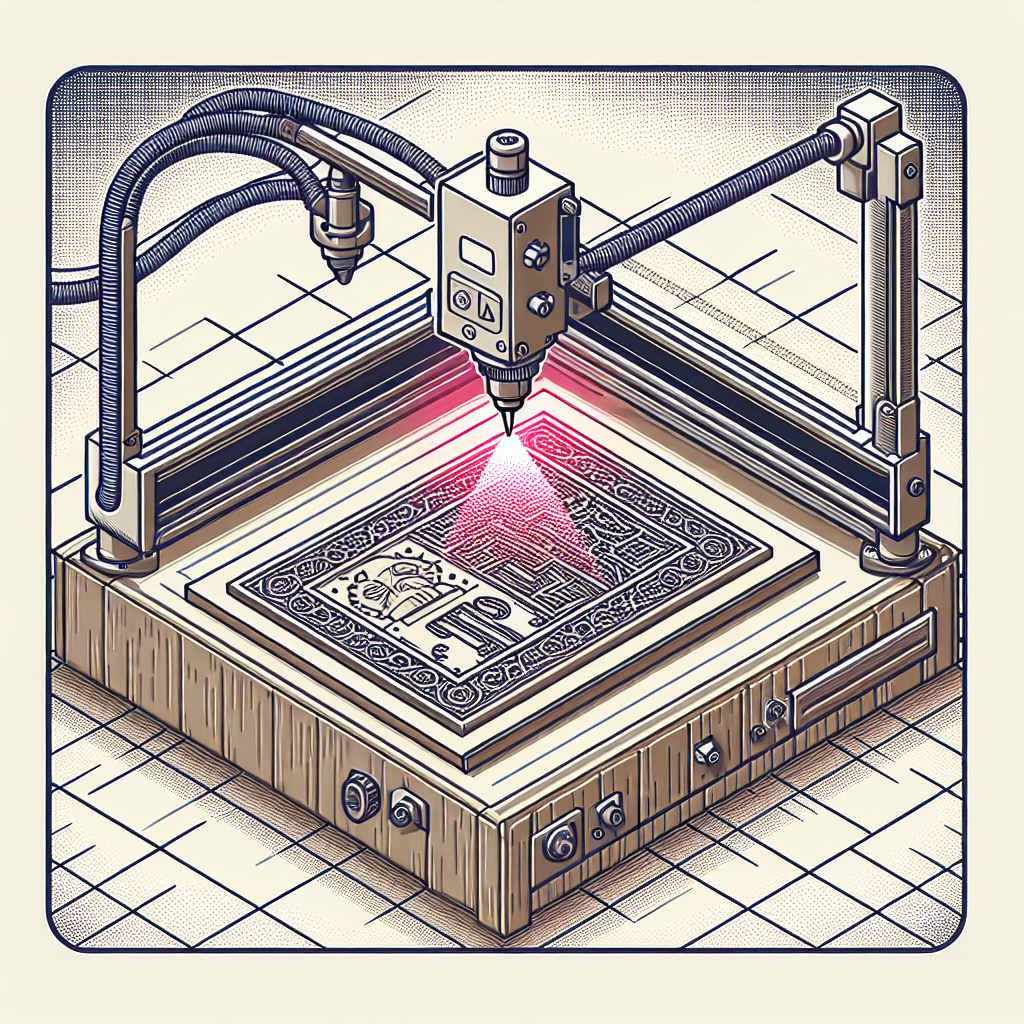

What is a Laser Cutter Acrylic Machine?

A machine uses a focused beam of light to cut and engrave materials with extreme precision. Unlike traditional cutting tools, laser machines are non-contact, meaning they don’t physically touch the material during operation. This makes them ideal for delicate or intricate designs that require smooth edges and clean cuts.

These machines are particularly popular for working with acrylic, a lightweight and durable plastic material used in various creative projects. Acrylic is easy to cut and engrave, making it a favorite among crafters, signage makers, and even architects. With the right settings, a laser cutter can create dazzling effects on acrylic, such as frosted textures or vibrant engraved patterns.

Why Choose a Laser Cutter Acrylic Machine?

There are several reasons why a laser cutter acrylic machine stands out among other cutting tools:

- Precision and Accuracy: Lasers can cut and engrave with micron-level precision, ensuring that even the most intricate designs are executed flawlessly.

- Versatility: These machines work with a wide range of materials, including wood, metal, glass, and fabric, in addition to acrylic.

- Ease of Use: Modern laser cutter acrylic machines come with user-friendly interfaces, making them accessible even for beginners.

- Speed: Once set up, laser cutting is much faster than manual methods, saving time and effort.

Are you wondering how a laser cutter acrylic machine compares to traditional tools? Let’s explore the key differences in the next section.

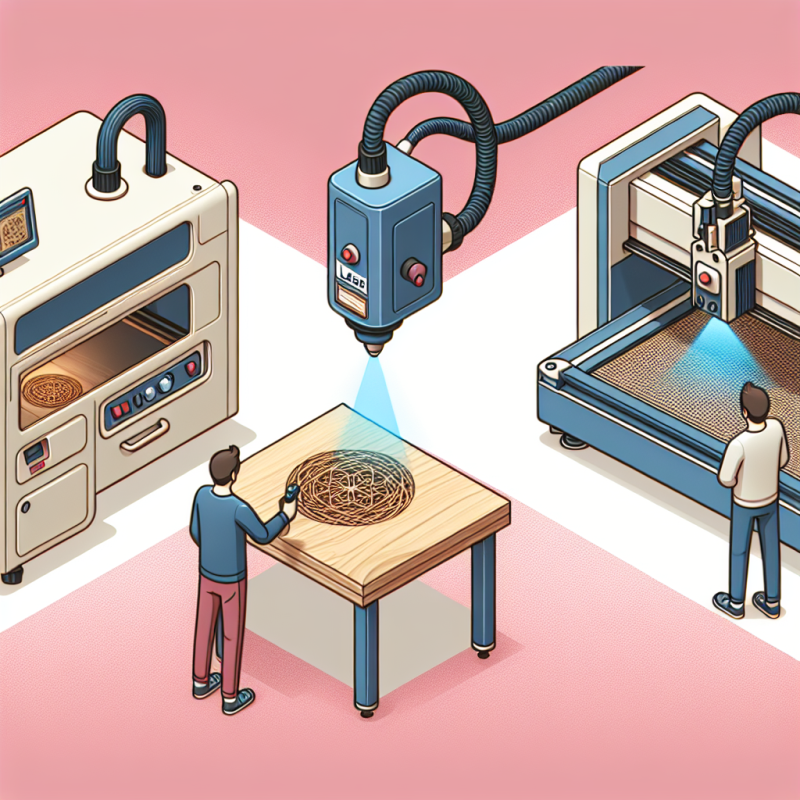

Laser Cutter Acrylic vs. Traditional Tools: What Sets Them Apart?

Compared to traditional cutting tools, a machine offers several advantages:

Cutting Quality: Laser cutting produces cleaner, smoother edges compared to manual or mechanical tools. This is especially important when working with materials like acrylic, where a rough edge can mar the finished look of your project.

Engraving Capabilities: Unlike traditional tools, laser machines can engrave intricate designs and text with exceptional detail. This makes them ideal for creating custom signage, personalized gifts, or artistic masterpieces.

Safety: Since there’s no physical contact during the cutting process, laser machines are generally safer to use. However, proper safety precautions, such as wearing protective eyewear and following machine guidelines, are still essential.

Applications of a Laser Cutter Acrylic Machine

The applications of a laser cutter acrylic machine are nearly limitless. Here are some common uses:

- Creative Projects: Artists and crafters use these machines to create decorative items, such as engraved acrylic wall art, custom jewelry, or intricate lampshades.

- Signage Making: Businesses rely on laser cutter acrylic machines to produce high-quality signs with precise lettering and designs.

- Prototyping: Engineers and designers use these machines to create prototypes for products, ensuring that the final design meets specifications before production begins.

- Cutting Shapes: From simple geometric shapes to complex patterns, laser cutter acrylic machines can handle a wide range of cutting tasks with ease.

Are you ready to take your projects to the next level? Let’s explore how to get started with a laser cutter acrylic machine.

Getting Started with Your Laser Cutter Acrylic Machine

If you’re new to laser cutting, here are some steps to help you get started:

- Familiarize Yourself with the Machine: Spend time reading the user manual and understanding the controls. Most modern machines come with intuitive interfaces, but it’s still important to know your way around before diving into complex projects.

- Select Your Material: Choose the right material for your project. Acrylic is a great starting point due to its ease of use and availability in various colors and thicknesses.

- Create or Import Your Design: Use design software like Adobe Illustrator, CorelDRAW, or even free tools like Inkscape to create your artwork. Many machines also support importing files directly from a USB drive.

- Set Up the Machine: Load your material onto the machine’s bed and adjust the settings according to your design requirements. Pay attention to factors like laser power, speed, and focus distance for optimal results.

- Test Your Settings: Before committing to a full project, run a test cut on scrap material to ensure everything is working correctly.

By following these steps, you can start creating stunning projects with your laser cutter acrylic machine in no time. Remember, practice makes perfect—don’t hesitate to experiment and refine your skills as you go along!

Safety Tips for Using a Laser Cutter Acrylic Machine

While laser cutter acrylic machines are generally safe, there are some precautions you should take to ensure a safe and enjoyable experience:

- Wear Protective Eyewear: Lasers emit bright light that can be harmful to your eyes. Always wear safety goggles when operating the machine.

- Avoid Flammable Materials: Keep flammable materials away from the work area, as lasers produce heat and sparks during operation.

- Ventilate Properly: Laser cutting can generate fumes, especially when working with plastics like acrylic. Ensure your workspace is well-ventilated or use a fume extractor to avoid inhaling harmful particles.

- Follow Manufacturer Guidelines: Always adhere to the safety instructions provided in the user manual to prevent accidents and extend the life of your machine.

Safety should always be your top priority when working with laser cutter acrylic machines. By following these tips, you can enjoy a safe and productive experience while creating amazing projects.

Frequently Asked Questions About Laser Cutter Acrylic Machines

Q: Can I use a laser cutter acrylic machine for cutting metal?

A: Yes, many laser cutter acrylic machines are capable of cutting and engraving metal. However, the type of laser and its power will determine the thickness and complexity of the material you can work with.

Q: Is it difficult to learn how to use a laser cutter acrylic machine?

A: While there is a learning curve, modern machines are designed to be user-friendly. With practice and patience, even beginners can master the basics in no time.

Q: What types of designs can I create with a laser cutter acrylic machine?

A: You can create virtually any design, from simple geometric shapes to complex patterns and text. The possibilities are limited only by your imagination!

The Bottom Line

If you’re searching for a tool that combines precision, versatility, and creativity, a is an excellent choice. Whether you’re creating decorative items, signage, prototypes, or custom designs, this versatile tool can help you bring your ideas to life. Just remember to prioritize safety and take the time to learn how to use your machine properly for the best results.

So why wait? Start exploring the world of laser cutting today and unlock a whole new level of creativity in your projects!

If you’re searching for a tool that combines precision, versatility, and creativity, a laser cutter acrylic machine is an excellent choice. Whether you’re creating decorative items, signage, prototypes, or custom designs, this versatile tool can help you bring your ideas to life. Just remember to prioritize safety and take the time to learn how to use your machine properly for the best results.

So why wait? Start exploring the world of laser cutting today and unlock a whole new level of creativity in your projects!