The Ultimate Guide to Laser Cutters for Fabric

Are you looking for precision, efficiency, and creativity in your fabric cutting projects? Look no further than the laser cutter for fabric! This revolutionary tool has transformed the way we work with textiles, offering unparalleled accuracy and versatility. Whether you’re a professional designer, a hobbyist, or a business owner, understanding how laser cutters work and how they can benefit your projects is essential. In this comprehensive guide, we’ll explore everything you need to know about laser cutters for fabric, including their benefits, applications, and how to choose the right one for your needs.

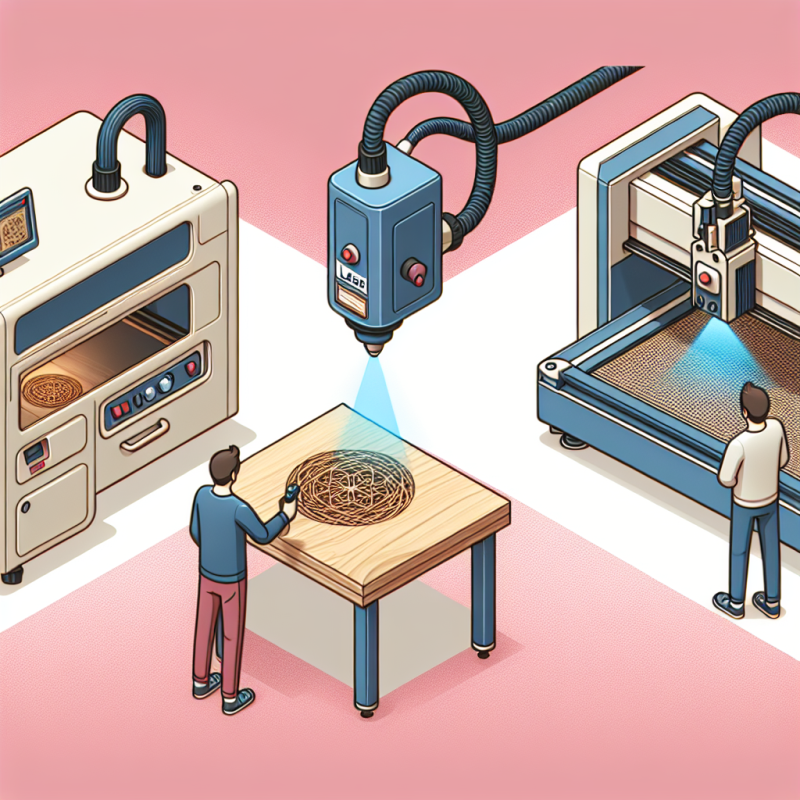

What Is a Laser Cutter for Fabric?

A laser cutter for fabric is a machine that uses a focused beam of light (a laser) to precisely cut or engrave materials. Unlike traditional cutting methods, which rely on blades or scissors, a laser cutter for fabric offers a non-contact method of cutting, ensuring minimal damage to the material and exceptional precision. The laser beam heats the fabric, causing it to melt or vaporize at the desired points, creating clean and seamless cuts.

This technology is particularly useful for intricate designs, patterns, and shapes that would be challenging or time-consuming to achieve manually. It’s widely used in industries such as fashion, upholstery, home decor, and even custom embroidery. If you’re wondering, “How does a laser cutter work?” the answer lies in its ability to combine advanced optics, computer-controlled movements, and high-powered lasers to deliver precise results every time.

Benefits of Using a Laser Cutter for Fabric

There are numerous advantages to using a laser cutter for fabric, making it an indispensable tool for many professionals. Here are some of the key benefits:

- Precision and Accuracy: Laser cutters provide unmatched accuracy, ensuring clean cuts even on intricate designs.

- Speed and Efficiency: The laser beam can cut through fabric quickly, reducing production time significantly compared to manual methods.

- Non-Contact Cutting: Unlike blade-based tools, laser cutters don’t physically touch the material, minimizing the risk of damage or fraying.

- Versatility: Laser cutters can handle a wide range of fabrics, from thin silk to thick upholstery materials.

- Customization: With computer-controlled software, you can create unique designs and patterns tailored to your needs.

If you’re asking yourself, “Why should I invest in a laser cutter for fabric?” the answer lies in its ability to enhance productivity, reduce waste, and elevate the quality of your projects. Whether you’re working on small-scale crafts or large-scale production runs, a laser cutter for fabric is a game-changer.

How Does a Laser Cutter Work?

To understand how a laser cutter works, let’s break it down into its basic components and processes:

- Laser Source: The machine generates a high-powered laser beam, typically using CO2 technology for fabric cutting.

- Optics: Mirrors or lenses focus the laser beam to a pinpoint, creating an intense heat source that melts or vaporizes the material.

- Computer-Controlled Movement: The machine is guided by software, which dictates the exact path of the laser beam based on your design.

- Cutting Table: A sturdy table supports the fabric and ensures stability during the cutting process.

The laser beam heats the fabric to a high temperature, causing it to melt or burn away at the designated points. This non-contact method ensures that there’s no physical stress on the material, resulting in smooth, precise cuts. If you’re wondering, “Can I use a laser cutter for delicate fabrics?” the answer is yes! With proper settings and adjustments, even delicate materials like silk or lace can be cut cleanly with a laser cutter for fabric.

Applications of Laser Cutters for Fabric

The versatility of laser cutting technology makes it suitable for a wide range of applications in the textile industry. Here are some common uses:

- Fashion and Apparel: Designers use laser cutters to create unique patterns, logos, and decorative elements on clothing, accessories, and footwear.

- Home Decor: From custom drapes to intricate upholstery designs, laser cutters enable the creation of beautiful and functional home decor items.

- Crafts and Artistry: Hobbyists and artists can use laser cutters to produce one-of-a-kind fabric art, patches, and embellishments.

- Custom Embroidery: Laser cutting is often used in conjunction with embroidery machines to create precise stencils or templates for intricate designs.

If you’re exploring “how to use a laser cutter for fabric,” the process involves designing your pattern using specialized software, setting up the machine, and letting it do the work. The result is a clean, professional finish that elevates your projects to the next level.

Choosing the Right Laser Cutter for Your Needs

With so many laser cutters available on the market, selecting the right one can be overwhelming. Here are some factors to consider when choosing a laser cutter for fabric:

- Type of Fabric: Consider the thickness and type of fabrics you’ll be working with. Some lasers are better suited for thin materials, while others can handle thicker textiles.

- Budget: Laser cutters vary widely in price, so determine your budget before making a purchase.

- Software Compatibility: Ensure the machine is compatible with your design software and operating system.

- Size and Portability: Think about how much space you have for the machine and whether portability is important.

- Additional Features: Look for features like automatic focus, multiple laser speeds, or built-in safety mechanisms to enhance your experience.

If you’re asking yourself, “Where can I find a reliable laser cutter for fabric?” consider checking out reputable brands and reading reviews from other users. Investing in a high-quality machine will pay off in the long run with better performance and durability.

Maintenance and Safety Tips

Like any precision tool, your laser cutter for fabric requires proper care to ensure optimal performance and longevity. Here are some maintenance and safety tips:

- Regular Cleaning: Keep the machine clean by removing dust and debris after each use.

- Lens Maintenance: Clean the laser lenses with a lint-free cloth to prevent smudges or scratches.

- Software Updates: Regularly update your machine’s software to ensure it’s running smoothly and securely.

- Safety Precautions: Always wear protective eyewear and follow safety guidelines when operating the machine.

By taking these steps, you can extend the life of your laser cutter for fabric and maintain its performance over time. Remember, a well-maintained machine is a safer and more efficient tool!

Future Trends in Laser Cutting Technology

The world of laser cutting technology is constantly evolving, with new innovations emerging to meet the demands of modern industries. Some exciting trends to watch include:

- Increased Automation: Future laser cutters may incorporate more automation features, reducing manual intervention and improving efficiency.

- Sustainable Practices: As sustainability becomes a priority, expect to see eco-friendly laser cutting solutions that minimize waste and energy consumption.

- Integration with AI: Artificial intelligence could play a role in optimizing laser cutting processes, ensuring even greater precision and customization.

If you’re curious about “how will laser cutters evolve in the future?” these trends suggest that they’ll become more advanced, user-friendly, and environmentally friendly. Stay ahead of the curve by exploring new technologies as they emerge!

Frequently Asked Questions About Laser Cutters for Fabric

If you’re still wondering “how does a laser cutter work for fabric?” or have other questions, here are some answers to common FAQs:

- How does a laser cutter work? The machine uses a focused beam of light to cut through materials with precision and accuracy.

- Can I cut multiple layers at once? Yes, depending on the thickness of your fabric and the power of the laser.

- Is it safe for all types of fabrics? Most modern laser cutters are safe for a wide range of textiles, but always test on scrap material first.

- How long does it take to learn how to use one? With practice and the right resources, you can become proficient in just a few hours or days.

If you’re still unsure about anything, don’t hesitate to reach out to experts or consult online resources for guidance. The more you know, the better equipped you’ll be to make the most of your laser cutter for fabric!

Conclusion

A laser cutter for fabric is an invaluable tool for anyone looking to create intricate and professional designs in the textile industry. With its precision, versatility, and ease of use, it’s no wonder that laser cutting technology has become so popular among designers, crafters, and manufacturers alike.

Whether you’re working on a small-scale project or running a large production line, investing in a high-quality laser cutter for fabric can take your work to the next level. Just remember to prioritize proper maintenance, safety, and continuous learning to get the most out of your machine.

If you’re ready to dive into the world of laser cutting, do your research, choose the right machine for your needs, and start creating stunning fabric designs today!

A laser cutter for fabric is a powerful tool that offers precision and versatility in textile design. Here’s a concise summary of its benefits, applications, and considerations:

Benefits:

– **Precision Cutting**: Creates clean, accurate cuts with minimal material waste.

– **Versatility**: Suitable for various fabrics, from delicate materials like silk to thicker textiles.

– **Customization**: Enables intricate designs, patterns, and logos for unique projects.

Applications:

– **Fashion & Apparel**: Ideal for designing unique clothing, accessories, and footwear.

– **Home Decor**: Perfect for custom drapes, upholstery, and decorative items.

– **Crafts & Artistry**: Allows hobbyists to produce one-of-a-kind fabric art.

– **Custom Embroidery**: Works with embroidery machines for precise stencils.

Choosing the Right Machine:

– **Fabric Type**: Consider the thickness and material of your projects.

– **Budget**: Balance quality and cost when selecting a machine.

– **Software Compatibility**: Ensure it works with your design software.

– **Size & Portability**: Choose based on available space and mobility needs.

– **Additional Features**: Look for safety mechanisms, adjustable speeds, etc.

Maintenance Tips:

– Regular cleaning to prevent dust buildup.

– Clean lenses to maintain accuracy.

– Update software for optimal performance.

– Follow safety guidelines, including wearing protective eyewear.

Future Trends:

– Automation enhancements for efficiency.

– Eco-friendly solutions aligning with sustainability goals.

– Integration of AI for advanced customization and optimization.

FAQs:

– **How does it work?** Uses a focused laser beam to cut materials.

– **Can it handle multiple layers?** Yes, depending on fabric thickness and machine power.

– **Safety**: Generally safe but test on scrap material first.

– **Learning Curve:** Quick to learn with practice and resources.

In conclusion, a laser cutter for fabric is an essential tool for anyone in textiles. By considering your needs, maintaining the machine properly, and staying informed about trends, you can elevate your projects to new heights. Happy creating!