Understanding Wood for Laser Cutter: Types, Benefits, and Applications

Laser cutting has revolutionized various industries, from manufacturing to artistry. One of the most popular materials used in laser cutting is wood, which offers unique properties that make it ideal for this technology. Whether you’re a hobbyist or a professional, understanding wood for laser cutter can open up endless possibilities for your projects. In this article, we’ll explore everything you need to know about using wood with laser cutters, including types of wood, benefits, applications, and tips for achieving the best results.

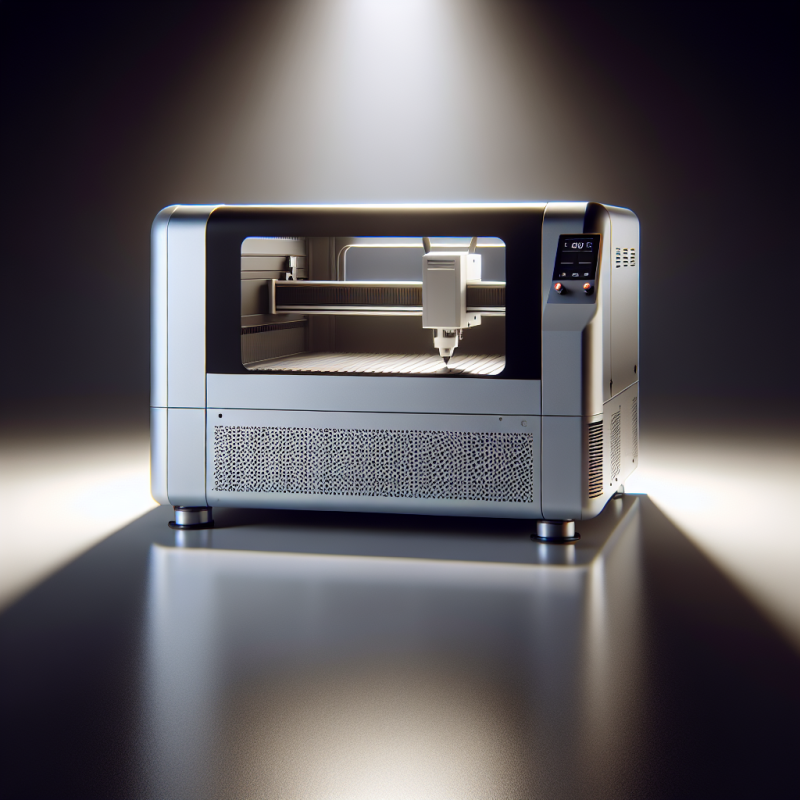

What Is Wood for Laser Cutter?

Wood for laser cutter refers to any type of wooden material that can be processed by a laser cutting machine. Unlike traditional woodworking tools, lasers offer precision and versatility, allowing intricate designs and patterns to be cut or engraved into the wood surface. This process is faster, cleaner, and more efficient than conventional methods, making it a favorite among designers and manufacturers.

But not all woods are created equal when it comes to laser cutting. Some types of wood may char excessively, while others may split or crack under high heat. To achieve the best results, you need to select the right type of wood for your project. Let’s dive into the different types of wood suitable for laser cutting.

Types of Wood Suitable for Laser Cutting

When choosing wood for laser cutter, it’s essential to consider factors like density, grain pattern, and moisture content. Here are some popular types of wood that work well with laser cutters:

- Plywood: Plywood is a versatile choice for laser cutting due to its smooth surface and consistent layers. It’s ideal for creating decorative items, signs, and furniture.

- Laminate Wood: Laminate wood offers a sleek finish and is resistant to wear, making it perfect for high-traffic areas like countertops or flooring.

- Basswood: Basswood has a soft texture and fine grain, making it easy to cut intricate designs. It’s commonly used in model-making and carving.

- MDF (Medium-Density Fiberboard): MDF is dense and uniform, providing excellent stability during laser cutting. It’s often used for decorative panels and signage.

- Acrylic with Wood Effect: For a wood-like finish without the natural imperfections, acrylic sheets with wood grain patterns are an excellent alternative.

Each type of wood has its own advantages and disadvantages. For example, while plywood is easy to cut, it may not be as durable as MDF. On the other hand, basswood offers exceptional detail but may require additional finishing to prevent warping. Experimenting with different types of wood can help you find the perfect match for your project.

Benefits of Using Wood for Laser Cutting

Why choose wood for laser cutter? Here are some compelling reasons:

- Precision and Accuracy: Lasers can cut intricate designs with pinpoint accuracy, ensuring clean edges and smooth surfaces.

- Versatility: Wood comes in various types, thicknesses, and finishes, allowing you to customize your projects according to your needs.

- Durability: Many types of wood are long-lasting and resistant to wear, making them ideal for functional items like furniture or decorative pieces.

- Aesthetic Appeal: Wood adds a natural beauty and warmth to projects, giving them a unique and professional look.

These benefits make wood an excellent choice for a wide range of applications. Whether you’re creating custom furniture, signage, or artistic pieces, wood for laser cutter can help you achieve your vision with ease.

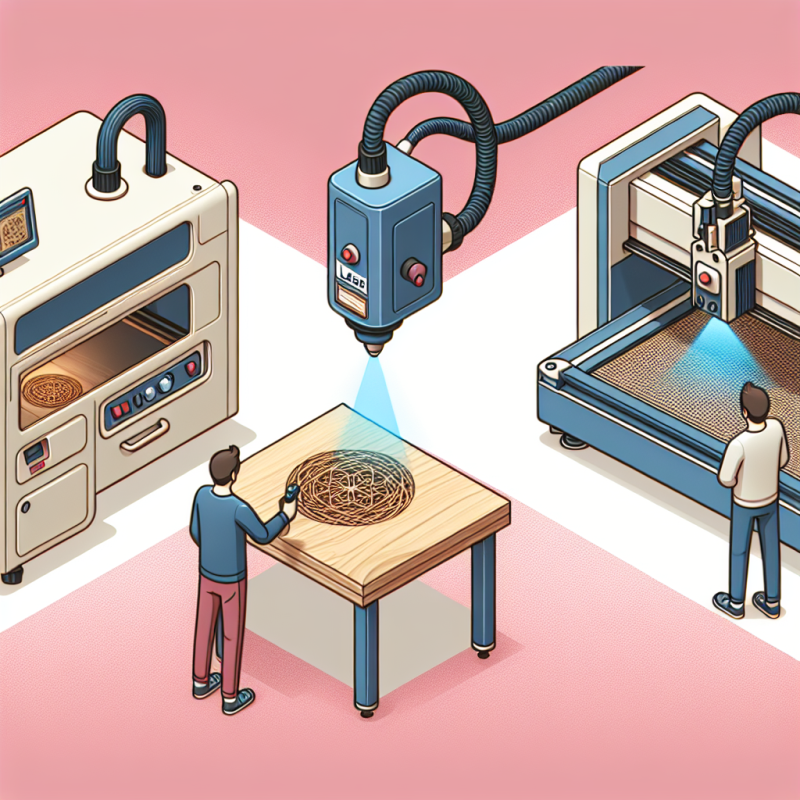

Applications of Wood in Laser Cutting

The versatility of wood makes it suitable for various industries and projects. Here are some common applications:

- Furniture Making: From chairs to tables, laser-cut wood allows for precise joinery and intricate designs.

- Signage and Decorations: Custom signs, plaques, and wall art can be created with ease using laser cutting technology.

- Hobby and Model Making: Scale models, toy parts, and custom gaming accessories are popular uses of wood in laser cutting.

- Flooring and Countertops: Laser-cut wood is used to create stylish and durable flooring and countertops with seamless joints.

- Packaging: Custom wooden boxes and crates can be designed for premium product packaging.

These applications demonstrate the wide range of possibilities when using wood in laser cutting. By combining creativity with advanced technology, you can bring your ideas to life in ways that were once unimaginable.

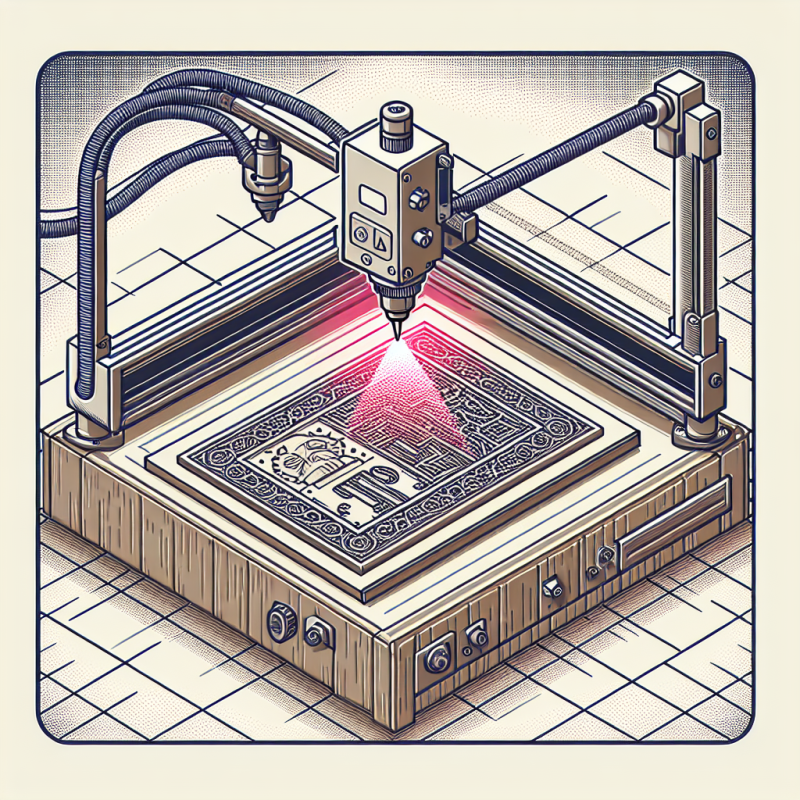

Tips for Working with Wood in Laser Cutting

To achieve the best results when working with wood for laser cutter, consider the following tips:

- Select the Right Material: Choose wood based on your project’s requirements, considering factors like thickness, grain pattern, and density.

- Preparation Is Key: Ensure the wood is clean, dry, and free of any contaminants before cutting. Sanding the surface can also improve laser performance.

- Adjust Laser Settings: Experiment with different power levels, speeds, and focal points to achieve the desired cut or engraving quality.

- Use Proper Safety Gear: Always wear protective eyewear and gloves when operating a laser cutter to prevent injuries from flying debris or hot materials.

- Post-Processing: After cutting, sand the edges for a smoother finish and apply a protective coating if needed to enhance durability.

By following these tips, you can maximize the potential of your laser cutter and create stunning wood-based projects with ease.

Frequently Asked Questions About Wood for Laser Cutter

Here are some common questions people have about using wood in laser cutting:

- Can all types of wood be used in laser cutting? While most woods can be cut with a laser, certain types may char or splinter more than others. Testing different materials is recommended to find the best option for your project.

- Do I need special equipment for cutting wood with a laser? Most standard laser cutters are capable of processing wood, but it’s essential to use appropriate settings and ensure proper ventilation to handle smoke and fumes.

- Can I paint or stain laser-cut wood? Yes, laser-cut wood can be painted or stained to enhance its appearance. However, it’s important to allow the wood to cool completely before applying finishes to avoid warping or discoloration.

Conclusion

Wood for laser cutter is a versatile and beautiful material that offers endless possibilities for creative and functional projects. By understanding the different types of wood, their benefits, and proper techniques for cutting, you can unlock your full potential as a designer or artisan. Whether you’re creating furniture, signage, or custom decor, wood combined with laser technology ensures precision, durability, and aesthetic appeal. So, what are you waiting for? Start exploring the world of wood for laser cutter today and bring your ideas to life!